Zhengzhou Success Machinery Co.,ltd - Professional valve manufacturer

News Events

Latest News

Introduction of the single orifice exhaust valve

Release time:

Jun 03,2024

The air release valve is also called exhaust valve / air valve that is a kind of valve to protect the safety of pipeline, it is usually installed in the highest point of pipeline. The main function is to remove the gas in the pipeline to ensure the stability of pipeline operation. this article is mainly to introduce the single orifice exhaust valve.

The air release valve is also called exhaust valve / air valve that is a kind of valve to protect the safety of pipeline, it is usually installed in the highest point of pipeline. The main function is to remove the gas in the pipeline to ensure the stability of pipeline operation. this article is mainly to introduce the single orifice exhaust valve.

The single orifice exhaust valve is divided into flange type air valve and threaded type air vlave, the only different is the way to connect the pipeline, but the internal structure and working principle is the same.

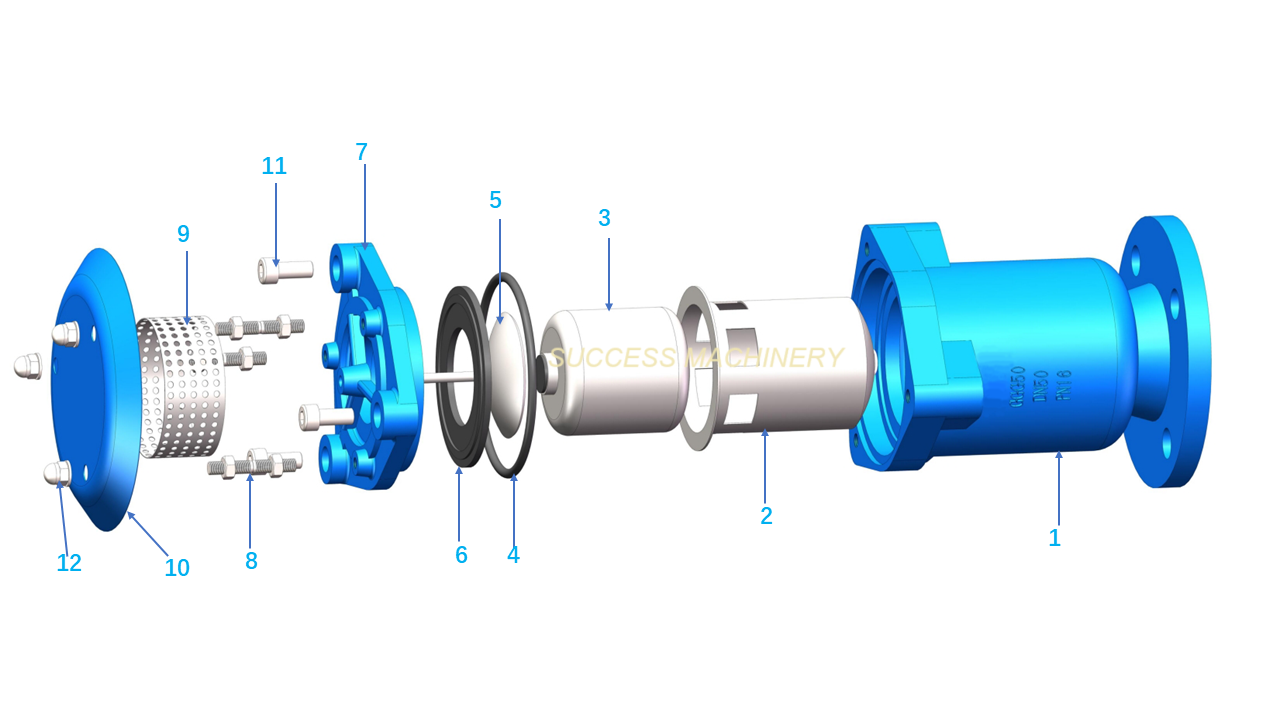

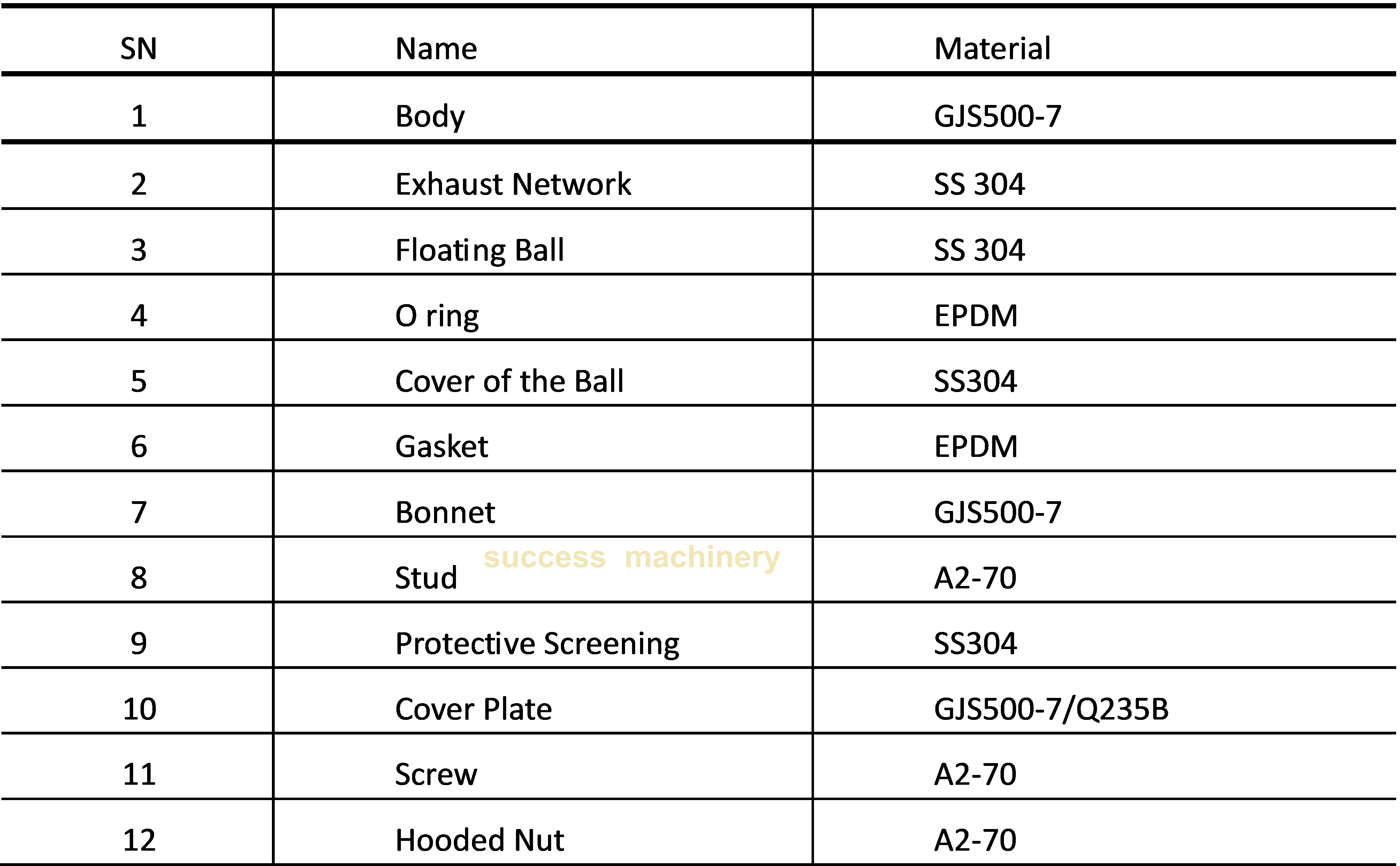

As pictured:

The exhaust valve consists of body, exhaust network, floating ball, cover of the ball and so on, it has about 12 parts. The structure is simple and easy to install, and it is usually installed on the water pipeline.

The work principle and function of the exhaust valve:

When water starts to be injected into the piping system, a large amount of gas in the piping is discharged out of the piping through the exhaust valve very quickly, which is the stage of large amount of exhaust from the exhaust valve. When the pipeline is filled with water, the float of the exhaust valve quickly rises to the closed state under the buoyancy of water, stopping the exhaust and preventing the outflow of water at the same time. It is well known that the average water contains about 2VOL % of dissolved air. In the process of water transmission, because of the temperature and pressure changes the gas in the water constantly escapes to the highest part of the pipeline gathered into the exhaust valve’s body. As more gas is added to the valve, the pressure rises, and when the gas pressure is greater than the system pressure, the gas causes the water surface to drop in the chamber, the floating ball drops with the water level, opens the small exhaust port at the top, and the small holes are automatically vented. When the gas is exhausted, the water level rises, the floating ball rises with it, and the exhaust port is closed. By the same token, when negative pressure is generated in the system, the water surface in the valve cavity drops and the exhaust port opens, Since the outside atmospheric pressure is greater than the system pressure at this point, the atmosphere will enter the system through the exhaust port, preventing the hazards of negative pressure.

Why all gas must be removed from the pipework:

First, a large number of air aggregation will cause the rupture of the pipeline: when it accumulates too much air in the pipeline, because the density of water is greater than air, the air and water are separated under the action of gravity of the water flow, restricting the normal flow of water, so that the water pressure in the pipeline rises, thus increasing the pressure of the pipeline. The pipe will then burst. when the pipe is under more pressure than the pipe material can withstand. Second, in the process of water flow, the air in the pipeline will not only increase the resistance of water, but also may make the water flow in the pipeline unstable, affecting the efficiency of the hydraulic system of the pipeline. Third, the air goes into the water pipe, The water is transported to the distance, then the air will be compressed and the formation of vibration waves, it is resulting in pipeline noise and pipeline vibration, affecting pipeline safety. Fourth, the air in the pipeline can not be discharged for a long time, that will cause the pipeline to rust and reduce the use of time.

Therefore, the exhaust valve plays a huge role in pipeline safety.

keywords

Previous Page:

Previous Page:

Follow Us

Zhengzhou Success Machinery Co.,ltd

TEL:+8618595868771

E-mail:sales@successmach.com

Address:98-1 Dengfeng Road, Shangjie District, Zhengzhou City, Henan Province