Zhengzhou Success Machinery Co.,ltd - Professional valve manufacturer

News Events

Latest News

Ball valve sealing principle analysis, holding fault judgment and troubleshooting

Release time:

Jul 30,2025

This article analyzes the sealing principle of the ball valve to determine the reasons for the ball valve hold dead, in advance to prevent the valve hold dead failure, so as to improve the reliability of the ball valve of the natural gas pipeline, extend the service life of the valve.

Ball valve sealing principle analysis, holding fault judgment and troubleshooting

一、Ball valve sealing principle analysis

Ball valves are generally composed of stationary parts (valve body) and closing parts (ball) two parts, through the closing parts (ball) around the center line of the valve body for 90º rotation to open and close the valve. Ball valves can be divided into two types of fixed-axis and floating-axis ball valves, we here mainly discuss the structure of fixed-axis ball valves and its sealing principle.

The sealing of the ball valve to the gas medium is realized by the soft seal formed by the close combination of the ball and the seat seal. Seat sealing principle varies with the different structure of the valve seat, can be divided into two main double piston effect (DPE) and downstream self-relief (SR).

Downstream self-releasing design ball valves are now mainly used in liquid pipelines, so this paper focuses on the wider application of double piston effect (DPE) design ball valves in the gas pipeline to analyze.

Double Piston Effect (DPE) valve seat structure and sealing principle analysis:

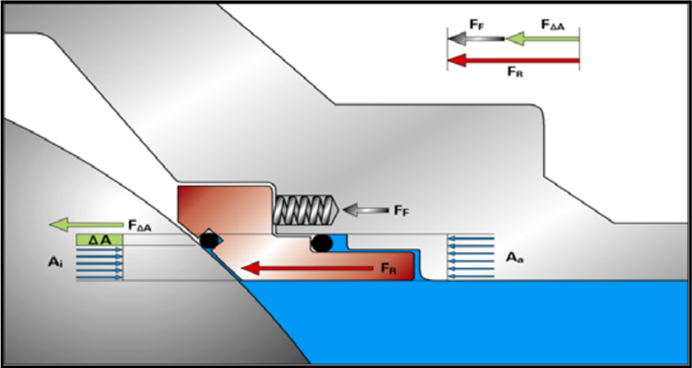

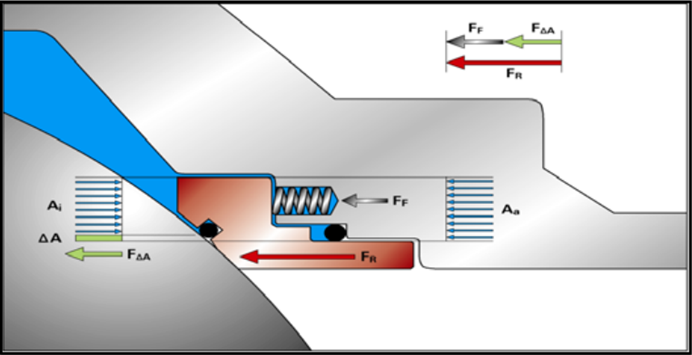

In the following double piston effect (DPE) sealing structure schematic, each force are described as follows:

FF-seat spring force

F△A-trunk/cavity pressure on the seat role of the combined FR FR- Combined force on seat

A-Combined force area

From Figure 2.1 and Figure 2.2, we can see that with the double piston effect structure (DPE) valve seat as the object of force analysis, the dry line pressure and cavity pressure on the seat force FR= FF+ F△A, the combined force FR direction is always pointing to the valve seat, that is, the dry line and the valve cavity pressure make the valve seat sealing ring to the ball pressure, and always realize a good sealing of the valve seat of the ball valve.

Figure 2.1 Schematic diagram of Double Piston Effect (DPE) structure and sealing principle (dry line pressure on seat force)

Figure 2.2 Schematic diagram of Double Piston Effect (DPE) structure and sealing principle (pressure of the valve cavity on the valve seat)

Both seats of the ball valve are designed with a double piston effect seat design, known as a double piston effect (DPE) design, which ensures that both seats of the ball valve seal at the same time. For Grove B-5 ball valves with balanced orifices, DPE seating is a standard design requirement. Due to the good sealing performance of the double-piston effect configuration, many valve manufacturers have begun to use similar double-sealed ball valve designs in recent years.

In practice, due to improper maintenance of the DPE ball valves or some of the DPE ball valve design specifications or the selection of the seal material is not appropriate, and these DPE excellent sealing design support has become one of the main causes of ball valve hold-up.

二、the ball valve holding fault judgment and exclusion

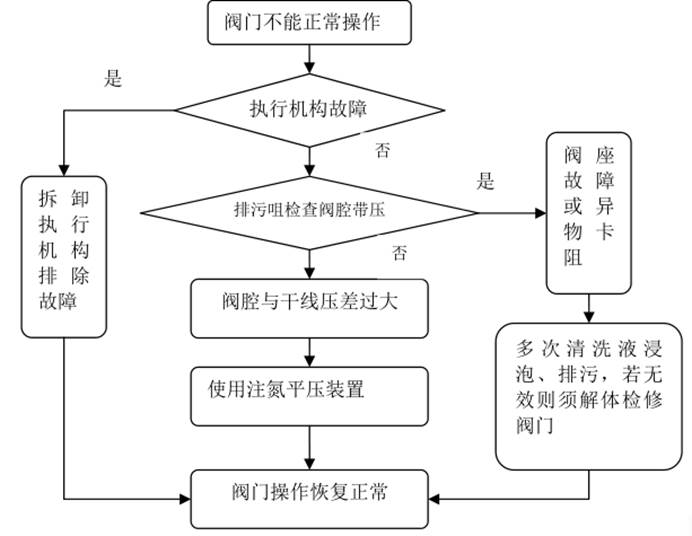

Ball valve holding fault judgment and troubleshooting flowchart

1、The main causes of ball valve holding failure and judgment method

Step 1: must first open the transmission gear box to determine whether the transmission gear box by serious corrosion, bearing damage or the existence of foreign objects jamming, resulting in the valve can not be operated normally. If the judgment is not the reason then enter the following steps.

Step 2: Sewage operation of the ball valve, if there is air pressure in the valve cavity, it can be preliminarily judged to be the cause of the hold for the sealing seat obstruction. Seal seat should be normal 0.003 inches of lateral movement space, if the injection of sealing grease hardening, dirt impurities stuck in the seat gap, or the sealing seat spring is not working properly can cause sealing seat obstruction, the ball valve hold dead.

Step 3: the ball valve sewage, if there is no air pressure in the cavity, it is judged to be too large a pressure difference between the valve cavity and the dry line caused by the ball valve hold dead. Valve cavity and the dry line pressure difference is too large, the sealing seat compression of the ball surface, the operating torque is too large, the ball valve hold dead can not be operated normally.

2、The ball valve hold dead fault troubleshooting

According to the ball valve sealing principle, fault cause analysis and ball valve hold dead fault field successful troubleshooting experience, summarize the hold dead fault troubleshooting methods are as follows:

(1) transmission gear box failure: as preventive maintenance, must be regularly opened every year gear box, check the box transmission mechanism lubrication, rust and components intact, clean up the box sewage, foreign objects, and replacement of fresh grease, if the bearings and other parts are damaged must be replaced in a timely manner to ensure that the transmission mechanism is in good working condition, the valve operates smoothly.

(2) sealing seat obstruction fault: first inject cleaning solution soak (soak time can be determined according to the valve grease injection), and then by discharging dirt impurities, eliminate sealing seat obstruction; if after repeated cleaning, sewage, the valve can not be operated normally, it can be judged to be the sealing seat springs and other parts of the abnormality, must be disassembled dismantle the valve for overhaul.

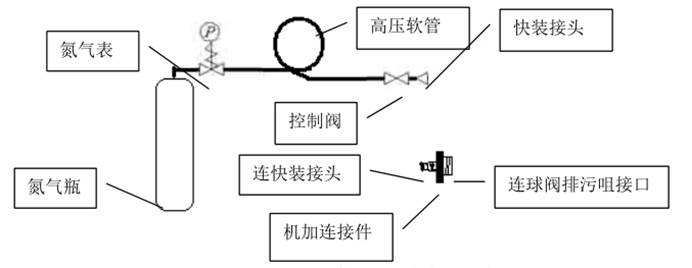

(3) the valve cavity and the trunk pressure difference is too large: generally the first injection of cleaning fluid soaking sewage, cleaning off the sealing surface of the original sealing grease, if the valve itself there is a certain amount of internal leakage, the valve can be realized with the trunk pressure balance; if the fault still exists, then consider making the sewage nozzle injection device connected to the ball valve sewage nozzle balance the valve cavity and the trunk pressure difference, to eliminate the hold failure. This set of flat pressure device structure is simple and easy to produce, and the effect is obvious, the use of this set of devices has been successful in solving my company, such as Dagang Station, a plant 12 "ball valves, and other valve hold dead failure. As shown in Figure 3.1 machine-added connectors at one end of the quick release couplings, one end of the interface specifications with the sewage nozzle screw buckle, it is recommended that engineers in accordance with the common valve sewage nozzle interface specifications to produce a set of machine-added connectors at any time standby.

Figure 3.1 Schematic diagram of nozzle air injection device

3、The hazards of barbaric operation

Barbaric operation of valves that can not be operated normally can lead to:

(1) valve drive gear box is overstressed, resulting in box rupture or box gear and other components deformation, damage;

(2) serious scratches on the sealing surface of the ball, resulting in serious internal leakage of the valve, or even scrapped;

(3) Fracture of the force lever or multiple simultaneous operation resulting in personal injury to the operator.

In order to avoid equipment damage, personnel injury and economic loss, the ball valve can not be operated normally, do not take the use of force lever or multiple operators and other barbaric way of operation! Must carefully analyze the cause of the failure after proper handling, troubleshooting.

三、The concluding remarks

In order to prevent the valve hold failure, improve the reliability of natural gas pipeline in the use of ball valves, to extend the service life of the valve, the following recommendations and preventive maintenance measures:

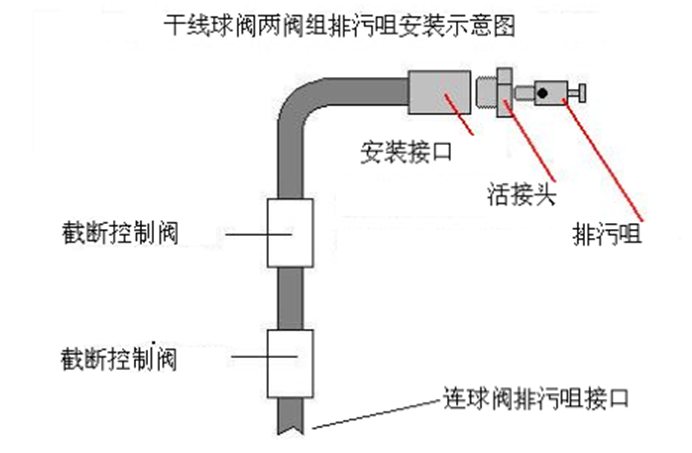

1、Improve the installation of sewage nozzle: ordinary ball valves sewage nozzle is installed directly into the valve body interface, due to the valve may have internal leakage, when the sewage nozzle faults or need to the valve cavity injection of gas leveling pressure, you must disassemble the sewage nozzle When the valve malfunctions or needs to inject air into the valve cavity to level the pressure, it is necessary to disassemble the drain nozzle to carry out maintenance, and the high-pressure medium that leaks into the valve cavity may pose a danger to the maintenance personnel. Therefore, it is recommended to promote the two-valve group design for the installation of dry line ball valve discharge nozzle, two control valves are installed in front of the discharge nozzle and connected to the valve body, and the discharge nozzle is installed after the control valve, in order to improve the convenience and safety of the related maintenance and overhaul operations. In addition, the two-valve discharge nozzle installation can also realize the large-diameter discharge, in order to reduce the risk of interception of ice blockage when gradually opening the discharge nozzle. This is shown in Figure 4.1 below.

Figure 4.1 Schematic Installation of Two Valve Groups of Trunk Ball Valves with Discharge Nozzles

2、Preventive maintenance: according to the valve maintenance and operating conditions, timely and appropriate amount of fresh grease injection, to prevent hardening of grease or sealing grease caused by jamming; regular full open / close the valve a few times, due to production and other reasons can not be full open / close the valve, at least regular activities 10 ° to 15 °, repeat the activities of several times with the full open / close the valve to play a nearly the same effect can be effective in preventing corrosion of the transmission mechanism and the valve Hold dead failure occurs.

3、Rregularly open the transmission gear box to check the transmission mechanism lubrication, rust and components intact, clean up the box of sewage, foreign objects, replacement and supplementation of fresh grease, if the bearings and other parts of the damage must be replaced in a timely manner to reduce the failure rate of the transmission mechanism.

4、Make a good record of sewage discharge, in order to analyze the gas gas in the pipeline and determine the sewage cycle.

keywords

Previous Page:

Previous Page:

Follow Us

Zhengzhou Success Machinery Co.,ltd

TEL:+8618595868771

E-mail:sales@successmach.com

Address:98-1 Dengfeng Road, Shangjie District, Zhengzhou City, Henan Province