Zhengzhou Success Machinery Co.,ltd - Professional valve manufacturer

News Events

Latest News

Why the eccentricity of butterfly valves is increasing

Release time:

Jun 09,2025

Butterfly valves are divided into centre-sealed butterfly valves, single eccentric-sealed butterfly valves, double eccentric-sealed butterfly valves, and triple eccentric-sealed butterfly valves according to the structure form. Why is the eccentricity of butterfly valve more and more? In order to make the butterfly valve has better sealing performance. The original butterfly valve is not closed tightly, also known as baffle valve. It is only used as a flow regulating valve in the piping system. With the development of science and technology, butterfly valve also to high temperature, high pressure, large diameter, high sealing, long life, excellent regulation performance direction.

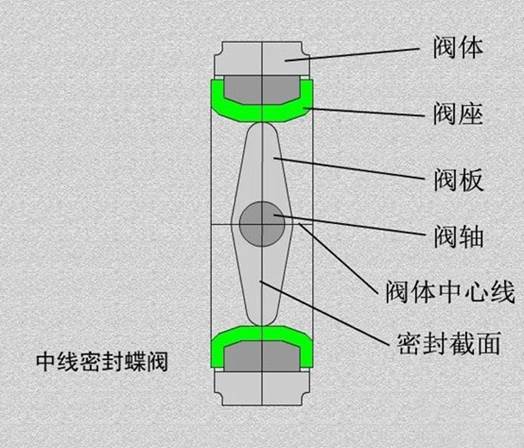

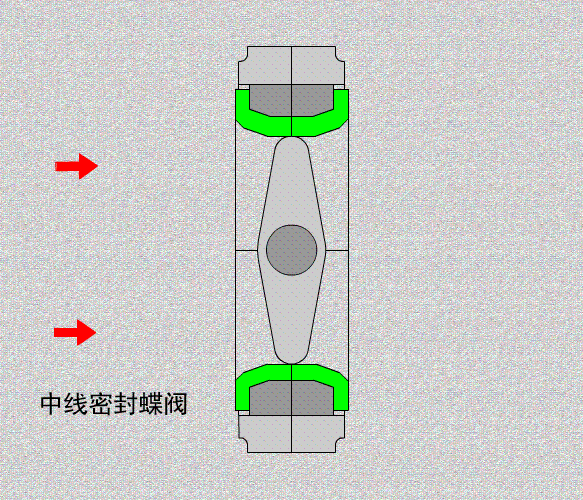

1、Centreline sealed butterfly valve

The sealing cross-section of the valve plate is in a straight line with the centre of rotation of the valve plate, and the centre of rotation of the valve plate is on the centre line of the valve body.

As the stem axis passes through the sealing section of the butterfly plate, it has some effect on the butterfly valve sealing. Mainly used for rubber seal, PTFE seal and other elastic sealing materials butterfly valve. Relying on the butterfly plate extrusion sealing valve seat, valve seat elastic deformation to form a seal. Wear and tear on the valve seat. Commonly used in the centre line butterfly valve D371X, D341X, etc..

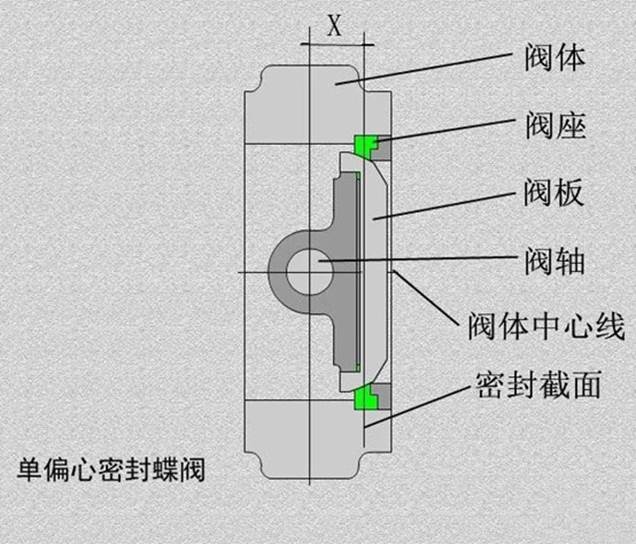

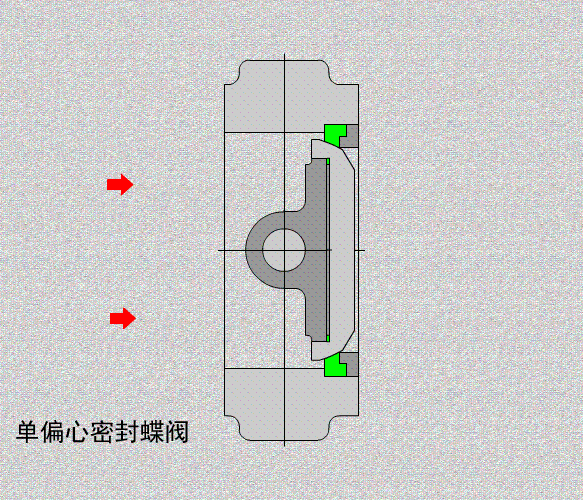

2、Single Eccentric Sealed Butterfly Valves.

The sealing section of the valve plate is offset from the centre of rotation of the valve plate by a distance X. The centre of rotation of the valve plate is on the centre line of the valve body.

As the stem axis deviates from the sealing section of the butterfly plate, the butterfly plate forms a complete circular sealing ring, which improves the sealing of the butterfly valve. In addition to rubber, PTFE and other elastic sealing materials, metal sealing valve seat is also used, which improves the temperature and service life of butterfly valve. Valve plate from 0 ° rotation 20 ~ 25 ° when the valve plate seal completely separated from the valve seat sealing surface. The wear and tear on the seat sealing surface can be reduced. The commonly used high vacuum butterfly valve Gi adopts this structure.

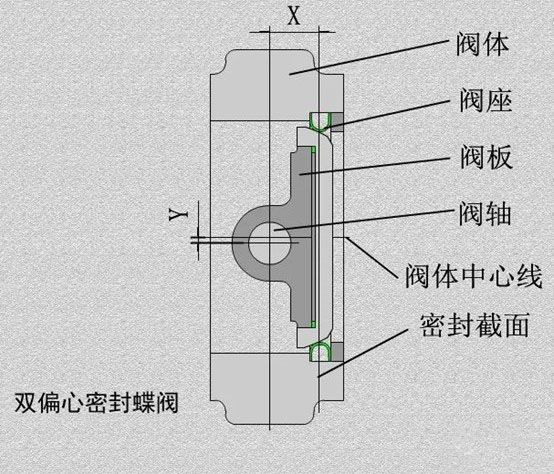

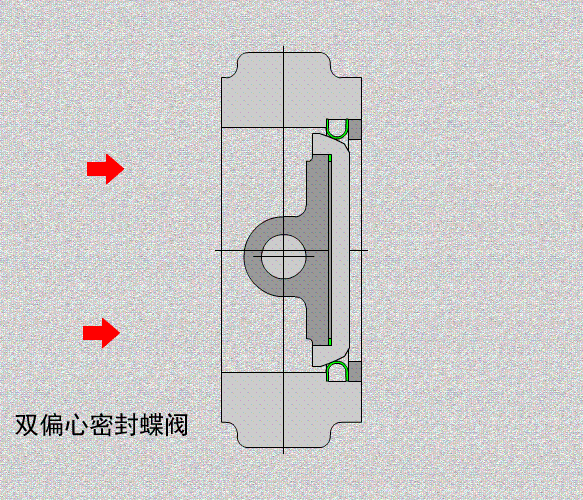

3、Double eccentric seal butterfly valve

The sealing cross-section of the valve plate is offset from the rotating centre of the valve plate by a distance X. The rotating centre of the valve plate is offset from the centre line of the valve body by a distance Y. An eccentric distance Y is added to the single eccentric sealing structure, so it is called double eccentric.

Nowadays, many high performance butterfly valves adopt this structure. Seat seal material can be rubber, PTFE, metal seat. When the valve plate rotates from 0° to 8~12°, the valve plate seal is completely detached from the sealing surface of the valve seat. The wear and tear on the valve seat is further reduced, and the sealing performance of the butterfly valve is improved.

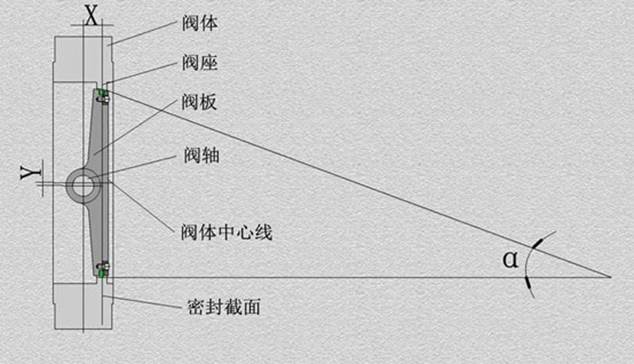

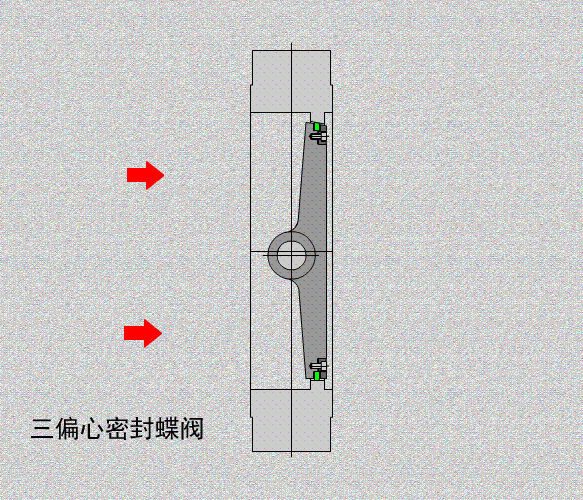

4、Triple Eccentric Seal Butterfly Valve

The sealing section of the plate is offset from the centre of rotation of the valve plate by a distance X. The centre of rotation of the valve plate is offset from the centre line of the valve body by a distance Y. The centre line of the valve body makes an angle α with the centre line of the sealing surface of the valve seat.

On the basis of double eccentric butterfly valve, the seat sealing surface is offset at a certain angle. Its seat sealing surface is conical. The valve plate seal will be detached from the seat sealing surface when it is opened. There is almost no friction between the two, which greatly improves the sealing performance and service life of the butterfly valve. The sealing pressure of the three eccentric butterfly valve is no longer provided by elastic deformation such as rubber and PTFE. Instead, a certain sealing pressure can be generated by the torque applied to the butterfly valve shaft. In this way, it can be used in high pressure pipelines and provide sufficient sealing. The valve plate or seat is designed with multi-layer metal elastic sealing structure. It can provide bi-directional sealing capability. Commonly used models D343H, D373H, etc.

Butterfly valve eccentricity gradually increase, is the butterfly valve continuous improvement, improve its performance process. Can gradually replace the large diameter gate valve, globe valve process.

keywords

Follow Us

Zhengzhou Success Machinery Co.,ltd

TEL:+8618595868771

E-mail:sales@successmach.com

Address:98-1 Dengfeng Road, Shangjie District, Zhengzhou City, Henan Province