Zhengzhou Success Machinery Co.,ltd - Professional valve manufacturer

News Events

Latest News

Manufacturing Process of the Double Eccentric Butterfly Valve

Release time:

May 01,2024

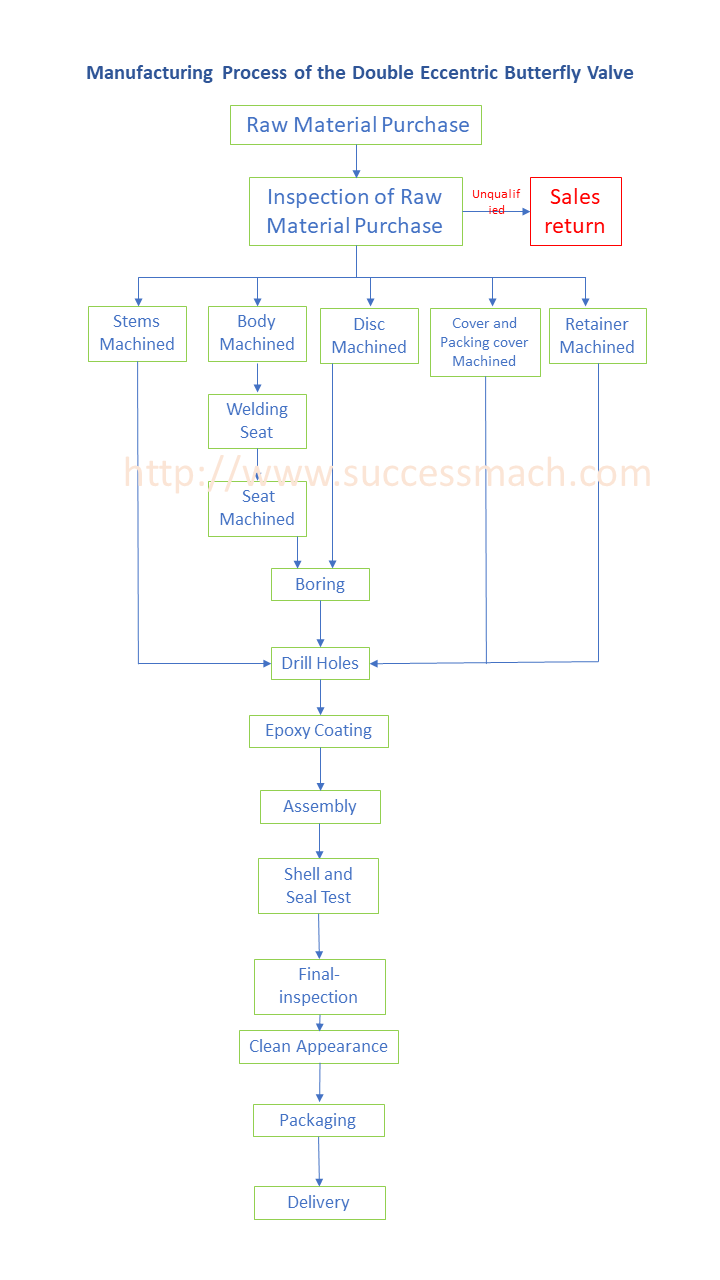

Double eccentric butterfly valve is our main product and compared with the industry, this product has obvious advantages. Production range is from DN80MM-DN4000MM, pressure is from PN6-PN40. it can ensures bi-directional sealing with zero leakage。 Therefore, the manufacturing process for the Double Eccentric Butterfly Valve is very professional. From the raw material coming into the factory, to the finished product delivery, each process has strict quality control. This production process is divided into 14 steps

Double eccentric butterfly valve is our main product and compared with the industry, this product has obvious advantages. Production range is from DN80MM-DN4000MM, pressure is from PN6-PN40. it can ensures bi-directional sealing with zero leakage。

Therefore, the manufacturing process for the Double Eccentric Butterfly Valve is very professional. From the raw material coming into the factory, to the finished product delivery, each process has strict quality control.

This production process is divided into 14 steps:

1、Raw material purchase.

2、Inspection of raw material purchase

3、Parts machining

4、Welding seat of valve body

5、Seat machined

6、Body and disc boring

7、Drill holes

8、Epoxy coating

9、Assembly

10、Shell and seal test

11、Final-inspection

12、Clean appearance

13、Packaging

14、Delivery.

Here is the flow chart:

keywords

Previous Page:

Previous Page:

Follow Us

Zhengzhou Success Machinery Co.,ltd

TEL:+8618595868771

E-mail:sales@successmach.com

Address:98-1 Dengfeng Road, Shangjie District, Zhengzhou City, Henan Province