Zhengzhou Success Machinery Co.,ltd - Professional valve manufacturer

News Events

Latest News

Methods of non-destructive testing(4)

Release time:

Mar 19,2025

This article focuses on MT,Other non-destructive testing methods will be introduced in subsequent articles.

Magnetic Particle Inspection (MT): “Visualizer” for Surface Defects

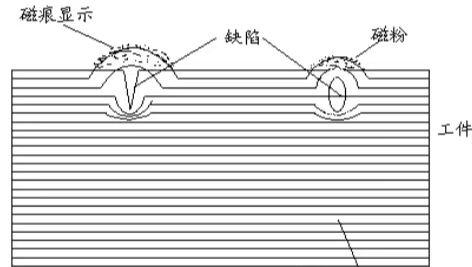

Agnetic particle inspection is the use of ferromagnetic materials in the magnetic field will be magnetized properties . When the valve is magnetized, if there are defects on the surface or near the surface (such as cracks, pores, inclusions, etc.), the magnetic lines of force will be distorted at the defects, forming a leakage field.

At this time, the valve surface is sprinkled with magnetic powder, the magnetic powder will be adsorbed by the leakage magnetic field, thus forming obvious magnetic marks at the defects, as if the defects are given a “mark”, so that the defects are clearly visible . This is like shining a flashlight on a hidden trap in the dark.

Magnetic particle inspection is mainly used to detect surface and near-surface defects in ferromagnetic materials (such as carbon steel, alloy steel, etc.) , in the inspection of valves, for valves made of ferromagnetic materials, such as carbon steel valves, magnetic particle inspection can quickly and accurately detect surface and near-surface defects . It is relatively simple to operate, has high detection sensitivity and can detect very small defects. Moreover, magnetic particle inspection can visualize the location, shape and size of defects, which is easy for inspectors to judge and analyze.

However, magnetic particle inspection can only be used to detect ferromagnetic materials, for non-ferromagnetic materials (such as austenitic stainless steel, copper, aluminum, etc.) can not be used . At the same time, it has limited ability to detect the depth of defects, and generally can only detect surface and near-surface defects. In addition, the roughness of the surface of the workpiece has certain requirements, the surface is too rough, which will affect the adhesion of the magnetic powder and the display of defects.

keywords

Previous Page:

:Next Page

Previous Page:

Next Page:

Follow Us

Zhengzhou Success Machinery Co.,ltd

TEL:+8618595868771

E-mail:sales@successmach.com

Address:98-1 Dengfeng Road, Shangjie District, Zhengzhou City, Henan Province