Zhengzhou Success Machinery Co.,ltd - Professional valve manufacturer

News Events

Latest News

D42X/H Type Double Eccentric Bidirectional Sealing Butterfly Valve Installation and Operation Manual

Release time:

Oct 20,2025

This document primarily outlines the installation and operating procedures for our company's double-eccentric, bidirectional sealing butterfly valve.

一. Product Application and Scope of Use:

This product may be extensively employed in pipelines for water supply and drainage, stone processing, power generation, chemical engineering, thermal energy, and municipal construction, serving to regulate flow or control the flow rate of media.

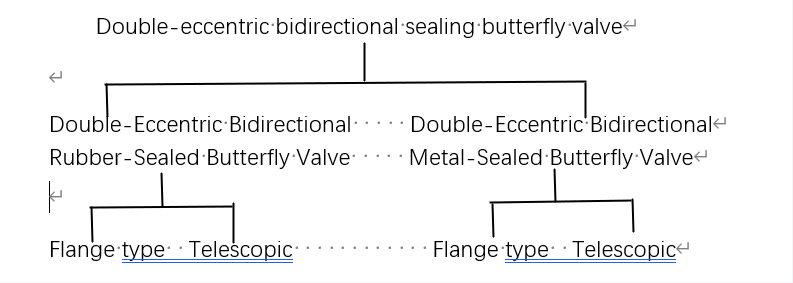

二. Product Structure Description

三. Storage and Safekeeping

1. Storage areas must be enclosed, clean and dry.

2. For long-term storage, the metal-sealed butterfly valve disc must remain in the closed position. Regular inspections and cleaning of the sealing surfaces are required to Prevent dust and sand from accumulating on sealing surfaces. When storing rubber-sealed butterfly valves, the butterfly disc must remain open at a 4°-5° angle, and take care to protect the sealing surfaces.

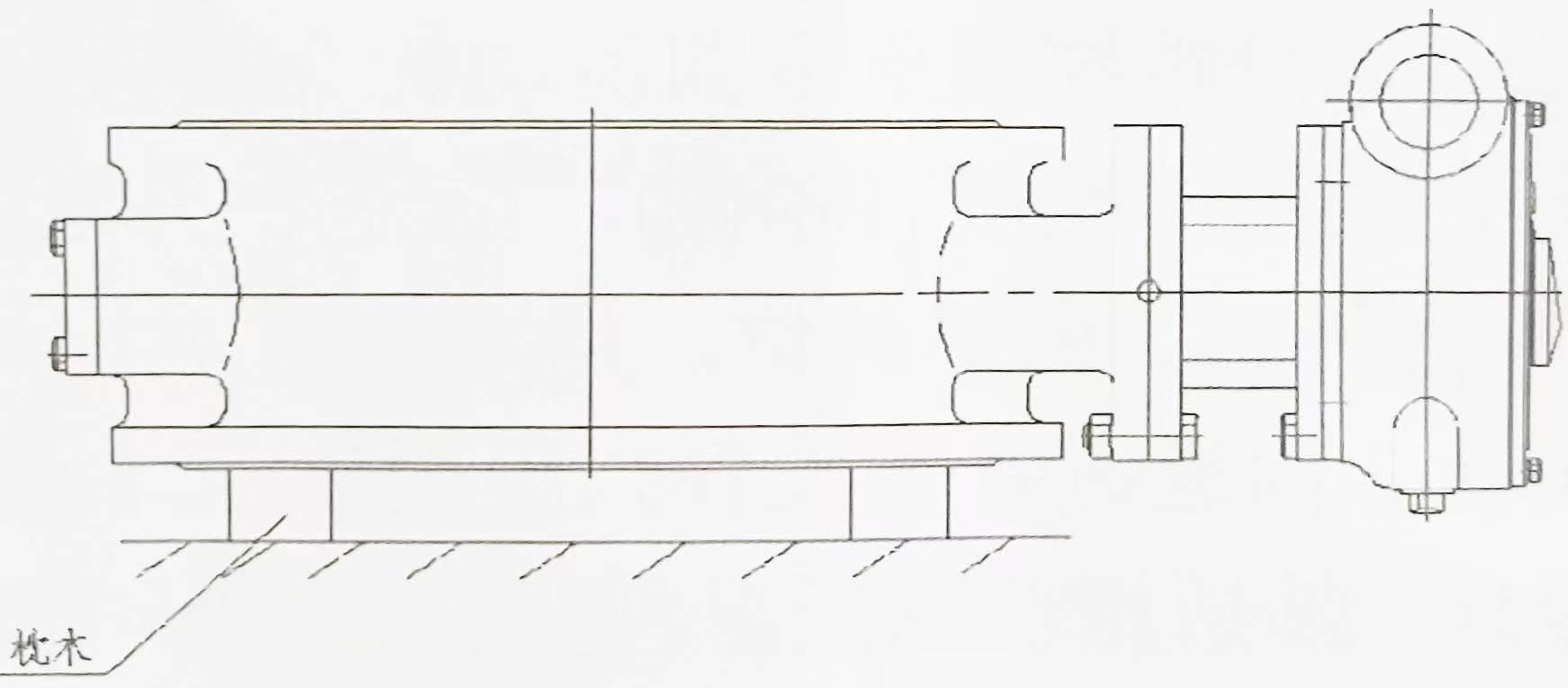

3. Valves must be stored with protective measures in place and shall not be stored exposed. Flange faces must not be placed directly on the ground but should be laid flat on wooden blocks (see Appendix 1) to prevent damage to the flange sealing surfaces. Whenever possible, use the original packaging and protective materials.

4. Regular Inspection: Check for aging rubber rings, rust on sealing surfaces, accurate scale readings, and normal worm gear rotation. Address any issues promptly.

四. Lifting Operations

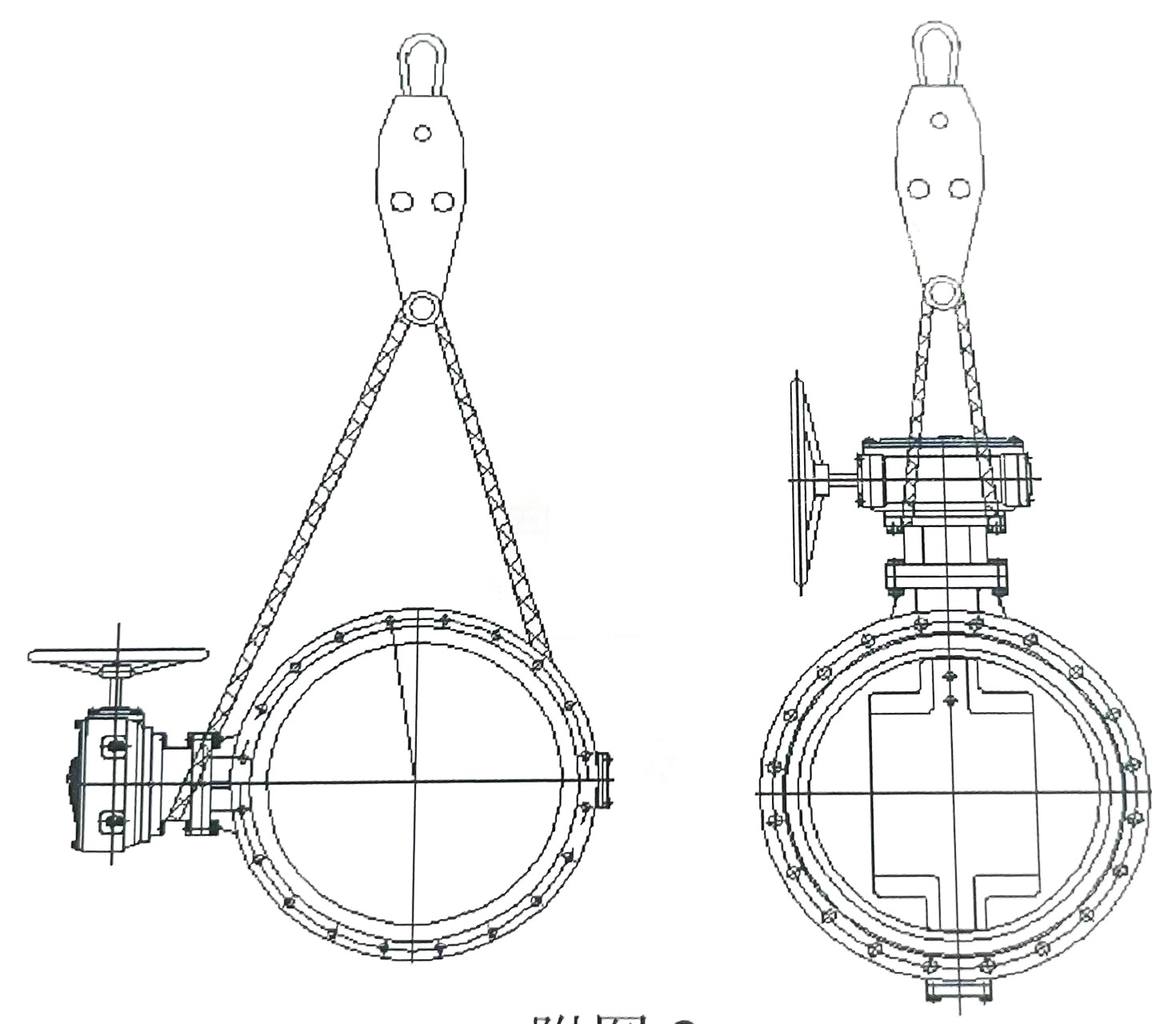

1. Select appropriate lifting equipment (fasteners, hooks, lifting ropes) based on valve weight. Lifting method shall follow Figure 2.

2. Lifting operations must be performed by qualified personnel (experienced individuals).

3. Determine the valve's center of gravity during lifting. Lifting ropes must be secured at positions ensuring the valve remains level.

4. For valves with diameters exceeding 800mm, lifting may be performed using the valve's lifting rings. The angle formed by the lifting ropes must not exceed 90°. Note: Valve lifting rings are only for lifting the valve body itself. Lifting valves connected to upstream/downstream stub pipes, expansion joints, or other pipeline fittings via the lifting rings may cause severe damage to the valve. Valves with diameters below 800mm should be transported as shown below.

5. Avoid collisions during gate valve hoisting.

五. Transportation

1. Valve transportation must be conducted by qualified entities and personnel.

2. When packaging valves for transport, pay special attention to the lifting points and center of gravity of the container to prevent overturning or sliding that could damage the product.

3. When transporting unpackaged valves, ensure proper protection of flange sealing surfaces, valve seat sealing surfaces, and valve disc sealing surfaces.

4. All packaged valves must be transported in compliance with local safety regulations. Pay particular attention to stacking restrictions—transport equipment must not stack valve boxes higher than three layers. Additionally, observe limitations on external dimensions and total weight.

六、Installation and commissioning

1. Before installing butterfly valves, inspect and remove any debris from the pipeline to prevent damage to the valve.

2. Prior to valve installation, verify that the flanges at both ends of the pipeline are parallel and aligned on the same axis to avoid valve deformation during installation.

3. Before installation, carefully verify that the operating conditions match the technical parameters on the valve nameplate.

4. After confirmation, remove dust and debris from the seat seal area and valve interior before opening or closing the valve.

5. Inspect all valve components for looseness. If isolated parts are loose but do not affect operation, tighten the bolts. Perform an empty rotation test to check for abnormalities: verify the accuracy of the valve's open/close positions. Operate according to the required number of turns indicated on the nameplate—clockwise for closing, counterclockwise for opening—while observing the pointer status.

6. Butterfly valves should not be installed on pipelines with free venting.

7. This butterfly valve features bidirectional sealing. When controlling unidirectional flow only, install the valve with the disc in the fully closed position.The arrow direction on the valve body indicates the primary pressure-bearing direction (i.e., the disc has a shaft side). Horizontal installation is recommended.

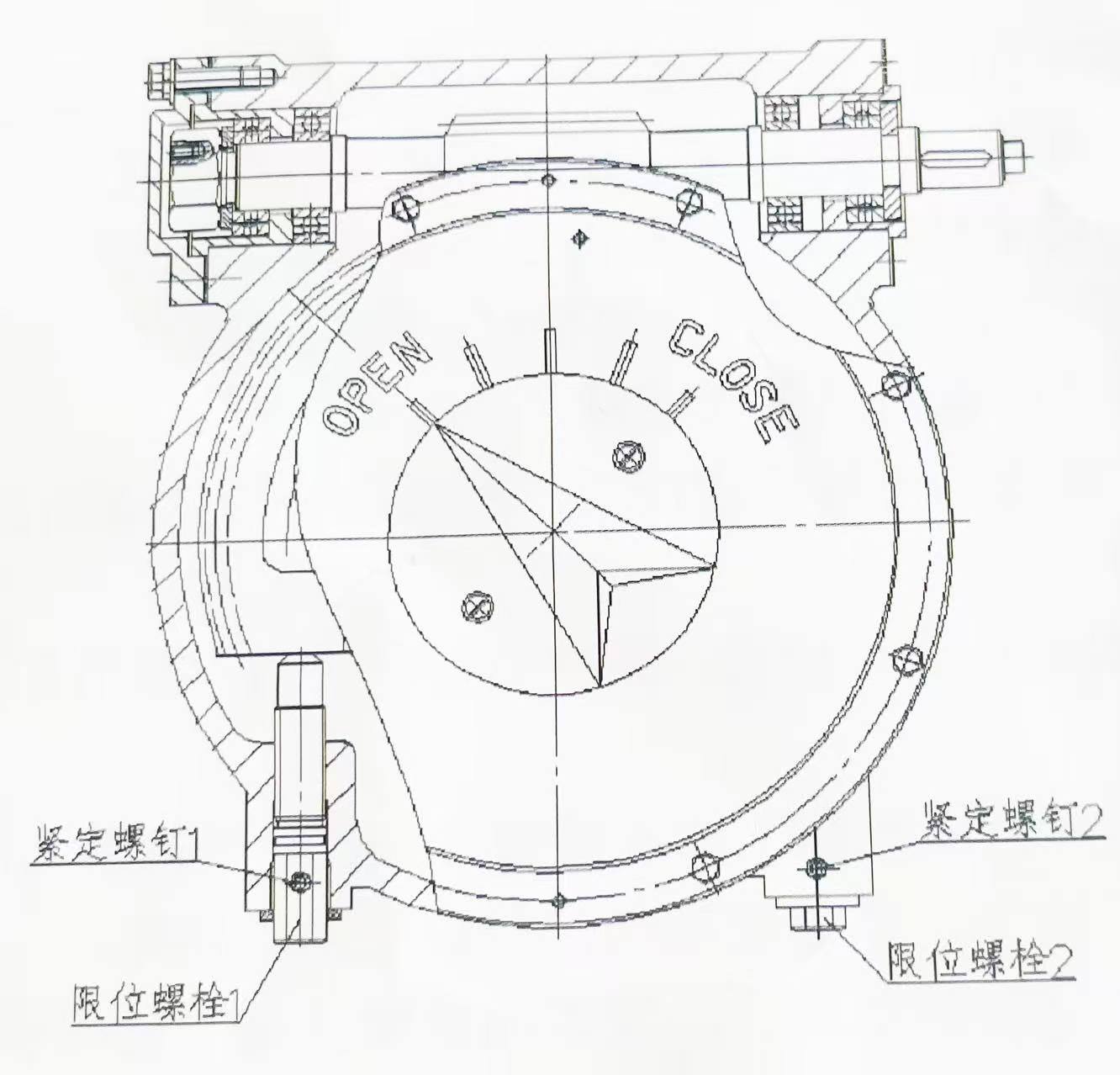

8. Adjusting Butterfly Valve Switching Position: If the butterfly disc seal surface does not close fully, use a hex wrench to loosen set screw 2 on the worm gear housing (see Figure 3). Then use an adjustable wrench to turn limit bolt 2 counterclockwise, taking care not to over-adjust. Similarly, if the butterfly disc does not open fully, use a hex wrench to loosen set screw 1. then use an adjustable wrench to turn stop bolt 1 counterclockwise until the disc is perpendicular to the sealing surface. Avoid over-opening.

Note: For limit adjustments on valves with protective covers, remove the cover before performing the above operations.

9. Install telescopic double-seal butterfly valves using the following method:

1) For new pipelines, it is recommended to install the expansion butterfly valve at its mid-length position (i.e., factory default setting).

2) For valve replacement in existing pipelines:

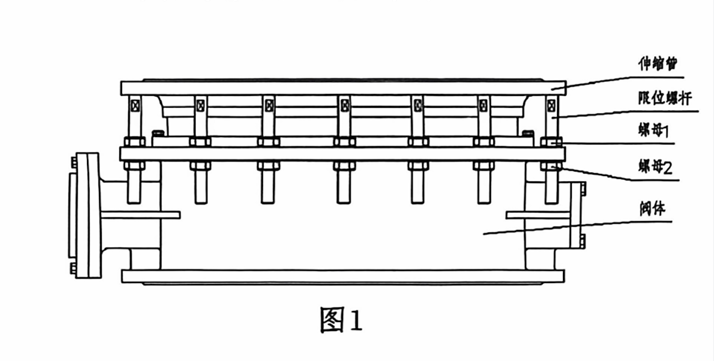

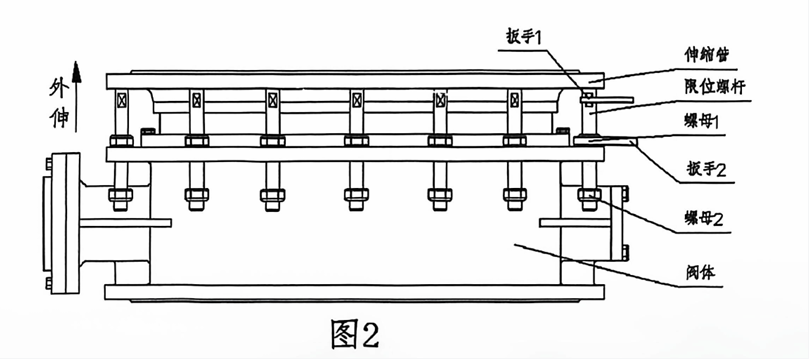

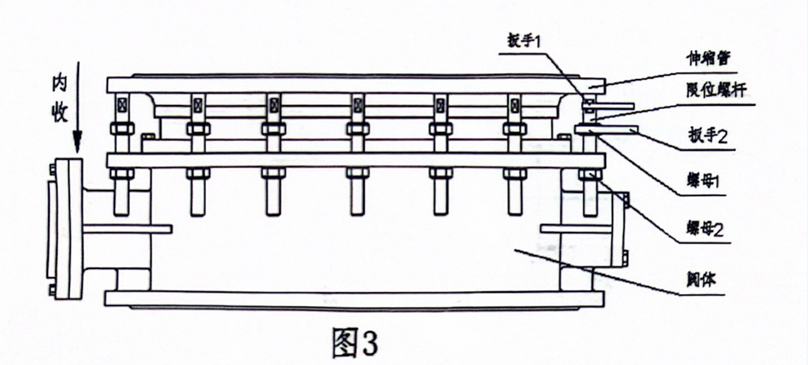

a.Use a wrench to secure the square head of the screw rod. Loosen Nut 1 and Nut 2. Adjust the length of the expansion butterfly structure according to on-site conditions. To extend the expansion tube: Secure the square head of the screw rod with a wrench, tighten Nut 1, and extend the expansion tube. See Figure 2. To retract the expansion tube: Secure the square head of the screw rod with a wrench and tighten Nut 2. This action retracts the expansion tube. See Figure 3. Then connect and secure the inspection door to the pipeline. However, the expansion tube must not exceed its rated expansion range (see nameplate).

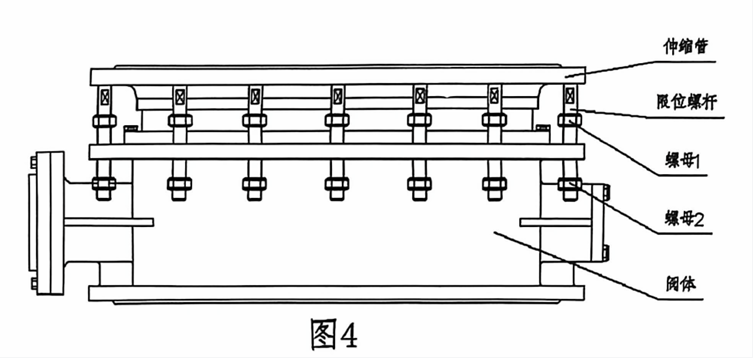

b.Rotate nut 2 symmetrically and evenly to press against the valve body flange, then tighten nut 1 (see Figure 1) to prevent extension/retraction of the flexible pipe. If the pipeline requires free extension/retraction of the flexible pipe for thermal compensation due to temperature differences, loosen both nuts 1 and 2. Ensure the circumferential distance dimensions of nuts 1 and 2 remain consistent (see Figure 4).

10. Disassembly: When removing the telescopic double-seal butterfly valve from the pipeline, first remove the bolts connecting the valve to the pipeline. Loosen nut 1, tighten nut 2, and retract the telescopic tube to disassemble.

11. For butterfly valves with a nominal diameter (DN) of 800 or larger, support and secure the piping at both ends of the valve, or directly support and secure the valve itself. When securing the valve, utilize the bottom feet and anchor bolts.

12. It is recommended that the valve installation location be positioned at least four times the pipe diameter away from the pump outlet or branch pipe inlet.

13. When installing extended-stem butterfly valves, supports should be installed at appropriate positions along the extended stem based on specific operating conditions.

14. Valves are equipped with open and closed position limiters, factory-set to optimal positions. Electric butterfly valves feature both electrical and mechanical limiters, while manual valves have only mechanical limiters. When adjusting valve positions, the adjustment range must not exceed 90±5°. Electrical limiters should be adjusted by qualified technicians following the electric actuator manual.

15. All bolts on the valve must be tightened symmetrically and sequentially. Do not tighten them in a circular pattern.

七. Operation and Maintenance

1. Users should inspect the product annually for abnormal conditions such as loose bolts, rusted components, or stuck valves.

2. When opening or closing valves with the handwheel, strictly follow the specified number of turns indicated on the label. Never operate the valve with multiple people simultaneously or use a lever to force it open or closed excessively, as this may damage the valve and worm gearbox.

3. For electric or pneumatic valves, strictly follow the operating instructions provided with the selected drive unit.

4. After valve installation, thoroughly clean the pipeline of debris such as sand, stones, rebar ends, welding rods, wood pieces, or tools. This prevents damage to the valve sealing surfaces during operation, which could compromise sealing performance.

keywords

Previous Page:

Previous Page:

Follow Us

Zhengzhou Success Machinery Co.,ltd

TEL:+8618595868771

E-mail:sales@successmach.com

Address:98-1 Dengfeng Road, Shangjie District, Zhengzhou City, Henan Province