Zhengzhou Success Machinery Co.,ltd - Professional valve manufacturer

Difference between muffler check valve and silent check valve

Release time:

Jun 11,2025

Difference between muffler check valve and silent check valve

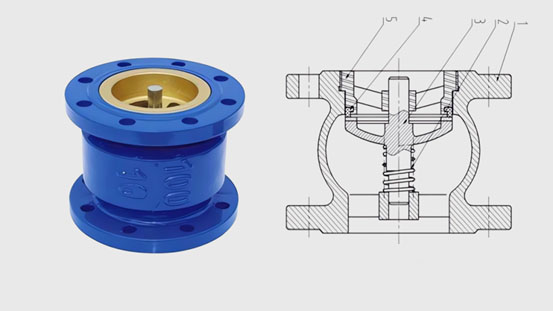

Muffler check valve is mainly used in the water system pipeline, installed in the water pump outlet. It is composed of valve body, valve flap, valve stem, spring and other parts. The closing stroke is short, and the speed of backflow is small at the moment of closing. The valve seal adopts rubber soft seal, spring reset makes the valve open and close without impact, reduce noise and water hammer effect, so it is called muffler check valve. Its spool adopts lifting structure, belongs to a kind of lifting check valve.

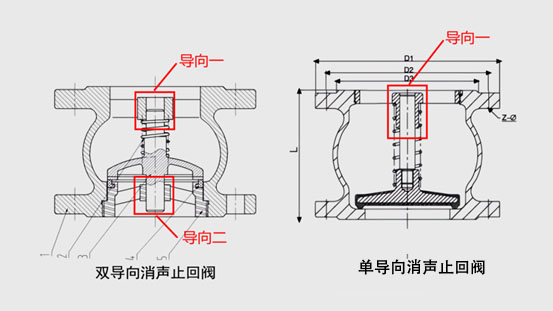

Muffler check valves are mainly installed vertically, but can also be installed horizontally for double side-guided spools.

But for large calibre valves, its flap weight is large, will guide the sleeve part will cause unilateral abrasion, serious impact on the sealing effect, so the large calibre is recommended to be installed vertically is better.

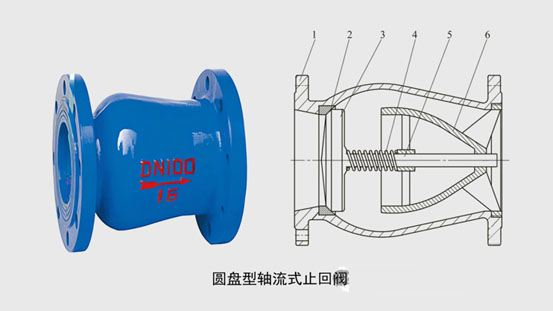

The standard designation of mute check valve is axial flow check valve. National standard GB/T21387-2008 axial flow check valve. Ministry of Machinery JB/T13460-2018 axial flow check valve for liquefied natural gas.

Axial flow check valve is a key equipment installed at the outlet of pump or compressor to prevent backflow of media. Because the axial flow check valve has the characteristics of strong flow capacity, small flow resistance, good flow pattern, reliable sealing and no water strike generated by opening and closing, it is widely used in the field of oil and gas long-distance pipeline, main water supply of nuclear power plant, compressor and large pumps in large-scale ethylene plant.

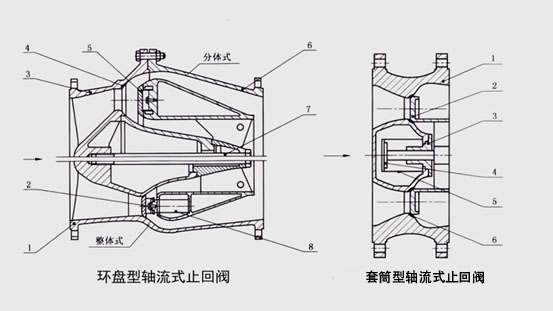

It is mainly composed of valve body, valve seat, valve flap, spring, guiding rod, guiding sleeve and guide cover and other parts. The surface of the inner cavity of the valve body, the guide cover, the valve flap and other flow surfaces should be streamlined, and the front is round and the back is pointed. Fluid in its surface mainly for laminar flow, no or little turbulence. The inner cavity of the valve body is a venturi structure, the fluid flow through the valve flow path is gradually narrowed, expanded process, minimising the generation of eddy current, small pressure loss, stable flow, no cavitation, low noise.

Structural forms are, disc type, ring disc type, sleeve type. It can be installed horizontally and vertically. Large diameter horizontal installation, the guiding rod should be double guided structure, to avoid excessive wear of the guiding sleeve and guiding rod unilateral caused by the self-weight of the valve flap. This will cause the sealing effect of the valve flap to be reduced and the noise to be increased when it is closed.

The difference:

1 valve structure is different. Muffled check valve structure is relatively simple, the flow path for the check valve conventional structure. Axial check valve structure is a little more complex, the valve body cavity for the venturi structure, the internal guide cover, the entire overflow surface is streamlined, the smooth transition of the flow path to reduce the vortex, effectively reduce the flow resistance.

2 spool seal structure is different. Muffler check valve with rubber soft seal spool, the entire spool wrapped in rubber processing, or the valve seat plus rubber ring seal. Axial check valve can be metal hard seal and surfacing cemented carbide, or soft and hard composite sealing structure, the sealing surface is more durable, prolonging the service life.

3 Applicable working conditions are different. Muffler check valve is mainly used for water systems and other room temperature pipelines, nominal pressure PN10 - PN25, diameter DN25 - DN500. material cast iron, cast steel, stainless steel. Axial flow check valves are more widely used, from low temperature -161 ℃ liquefied natural gas to high temperature steam. Nominal pressure PN16-PN250, American Standard Class150-Class1500. diameter DN25-DN2000.

4 Connection methods are different. Muffler check valve connection mode has flange connection, clamp connection, groove connection. In the fire pipeline, groove connection is widely used. Axial flow check valve has flange connection, butt-clamp connection, butt-welding connection. In the oil and gas, nuclear power plant pipeline, most of the butt welding connection.

keywords

Follow Us

Zhengzhou Success Machinery Co.,ltd

TEL:+8618595868771

E-mail:sales@successmach.com

Address:98-1 Dengfeng Road, Shangjie District, Zhengzhou City, Henan Province